We are ISO:9001:2015 Certified

We pride ourselves in Precision Abrasive Cutting. This is how it all began 80 years ago. D & H uses in house custom built, cutoff machines to hold close tolerances and produce burr free parts. By holding close tolerances, it will eliminate many secondary operations for our Customers.

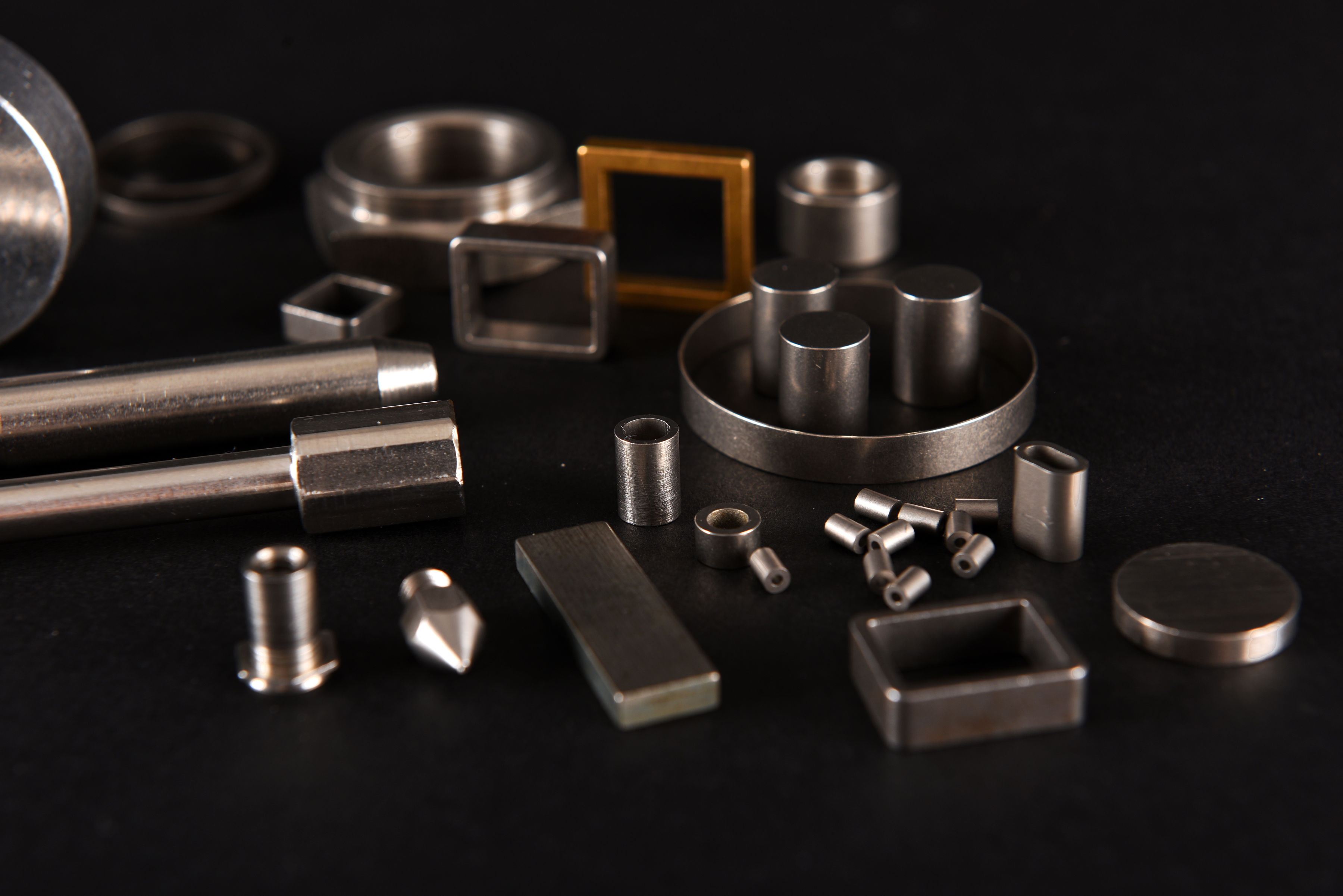

Much of our specialized work is in the Aviation slugs, Dental Alloys and Super Alloys, Tubing, Pins, Crimps, Ferrules. All types of shapes and sizes. We use thin abrasive wheels, which means minimal material loss. With our high speed capabilities and quick turnaround times, we ensure quality and service that our Customers depend on. There is no quantity too small or too big.

Capabilities

Diameter .006 to 4”

Quantity Sample Lots to Large Production

Lengths .010 to 6’

Equipment

6 D & H Semiautomatic cutoff saws

16 D & H Automatic cutoff saws

1 Campbell 16″ saw

1 Campbell 20″ saw

Materials

Alloys Alnico Aluminum Brass Copper Tungsten

Carbon Copper Hastelloy Inconel Kovar

Moly Monel Nickel Steel Tantalum

Titanium Tungsten Waspaloy

CENTERLESS GRINDING:

D & H is equipped to offer a wide range of Centerless Grinding Services; from short pins to long bars. We accept small and large quantity orders.

Capabilities

Diameter .062 to 3″

Precision Part or Bars

Tolerance up to +/- .0001

Equipment

4 Cincinnati #2

3 Cincinnati # 2L0

1 Cincinnati # 220-8

1 Royal Master